Doctoral Student: Laurence Crouzet

The machine and information age led the transition from industrial to digital design and fabrication in architecture. This fundamental change impacts how the construction process and its resulting objects are preserved. Knowledge about building materials, construction techniques, and assembly processes is now preserved digitally or dismissed. The loss, corruption, or absence of data challenges and complicates the maintenance, repair, and adaptation of buildings.

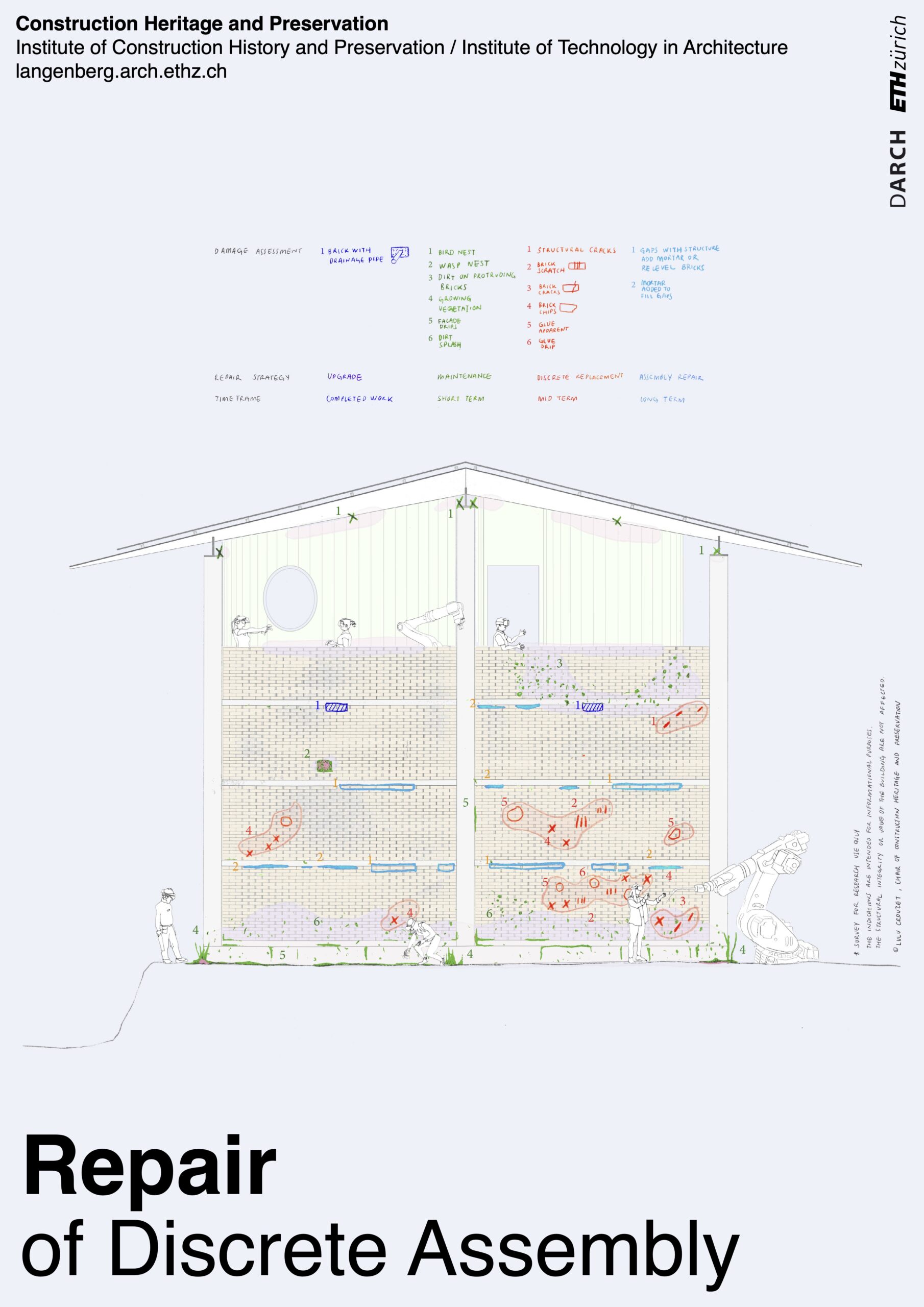

The research focuses on repairing digitally fabricated architecture and ensuring the long-term preservation of related born-digital data. Case studies are analyzed to identify damages, develop repair strategies, and derive insights. These artifacts, computationally conceptualized and/or robotically fabricated, face data loss due to technical obsolescence, organizational changes, and lack of archival concern, alongside physical degradation from weathering, aging, and use. Both digital and physical environments require maintenance and repair.

Approaches leveraging original or related technologies such as fabrication-aware design, motion capture, robotic manufacturing, coding, human-machine collaboration, and augmented reality will be implemented for authentic protocols. Repairing born-digital architecture furthers the documentation, transfers pertinent data, and favors the transmission of intangible cultural heritage while preserving digital craftsmanship methods of discretely assembled buildings. By shifting the attention from the built object to the fabrication process, the research addresses the impending problems of preserving significant digitally fabricated buildings and encourages their creative adaptation. This promotes social sustainability by integrating tacit and cognitive knowledge from the concept to the fabrication. It values repair over replacement or recycling, which lowers environmental and economic hardships, maintains material and assembly heritage, and upkeeps technical craftsmanship.

This research is part of the Digital Construction Archive project and funded by the Swiss National Science Foundation (SNSF). The case studies are part of the National Centre of Competence in Research (NCCR) Digital Fabrication (DFAB).